Capabilities

CNC MILL DEPARTMENT

HYUNDAI-WI F-500

Vertical Milling Center with 4th Axis

HYUNDAI-WI F-500

Vertical Milling Center with 4th Axis

AKIRA SEIKI SV 1000

Vertical Milling Center with 4th Axis

SWISS DEPARTMENT

CITIZEN A20 VII

Sliding Headstock type CNC Automatic Lathe

CITIZEN A20 VII

Sliding Headstock type CNC Automatic Lathe

CITIZEN A20 VII

Sliding Headstock type CNC Automatic Lathe

CITIZEN A32

1 1/4″ capacity Sliding Headstock type

CNC Automatic Lathe

EUROTECH 42 SLY-B

Swiss Turn with B Axis (1 1/2″ Tube Capacity)

WELDING DEPARTMENT

LINCOLN HELI-ARC

welder with rotary table

MILLER HELI-ARC

welder rotary table

MILLER HELI-ARC

welder rotary table

MILLER HELI-ARC

welder rotary table

CNC LATHE DEPARTMENT

MIYANO BNE51 SY

Twin Spindle, multi Axis turning center with live tooling and Y Axis. (2″ Bar capacity)

MIYANO BNE51 SY

Twin Spindle, multi Axis turning center with live tooling and Y Axis. (2″ Bar capacity)

MIYANO 42 DHY

Multi Axis turning center with Y axis

MIYANO 42 DHY

Multi Axis turning center with Y axis

HYUNDAI-WIA 1800 TTSY

Twin Spindle, multi Axis turning center with Live tooling and Y Axis (2 1/2″ Bar capacity)

HYUNDAI-KIA SKT250

Twin spinde, multi Axis turning center. (3″ Bar Capacity)

HYUNDAI-KIA SKT 21LMS

Twin Spindle, mutli Axis turning center with Live tooling. (2″ Bar capacity)

HYUNDAI-KIA SKT 21LMS

Twin Spindle, mutli Axis turning center with Live tooling. (2″ Bar capacity)

AKIRA SEIKI SL 20

CNC Turnng center

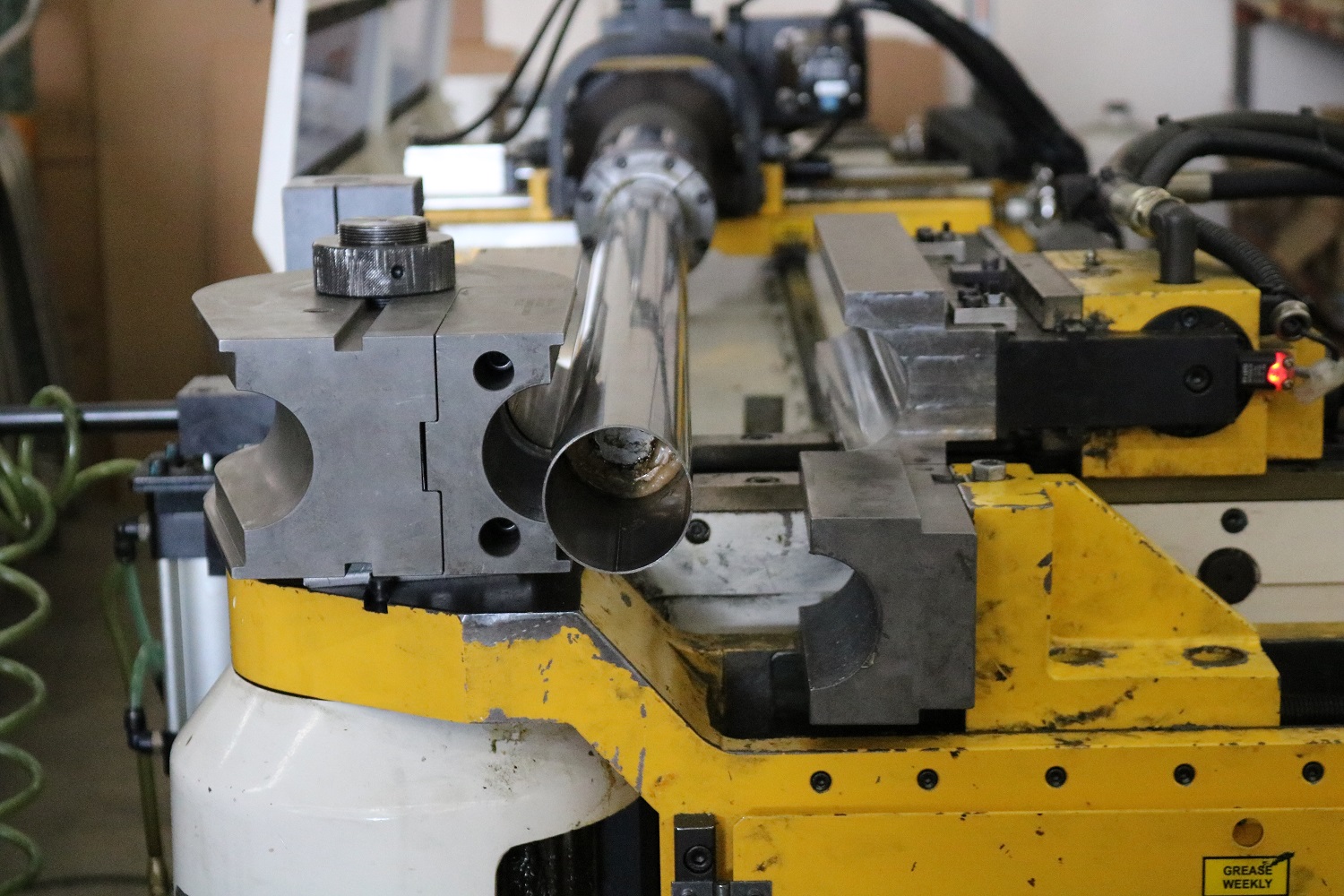

CNC BENDING DEPARTMENT

SB-63 SOCO

Automatic CNC Tube Bender (2 1/2″ Tube Capacity)

SB-39X9A SOCO

Automatic; multi Axis CNC Tube bender (1 1/2″ Tube Capacity)

CNC SAW CUTTING DEPARTMENT

HYDMECH H11A CNC

Automatic saw cutting with 11″ bar capacity

QUALITY CONTROL DEPARTMENT

HEXAGON METROLOGY 7.10.7 CMM SF PC-DMIS Software

HEXAGON METROLOGY Romer Absolute Arm PC-DMIS Software

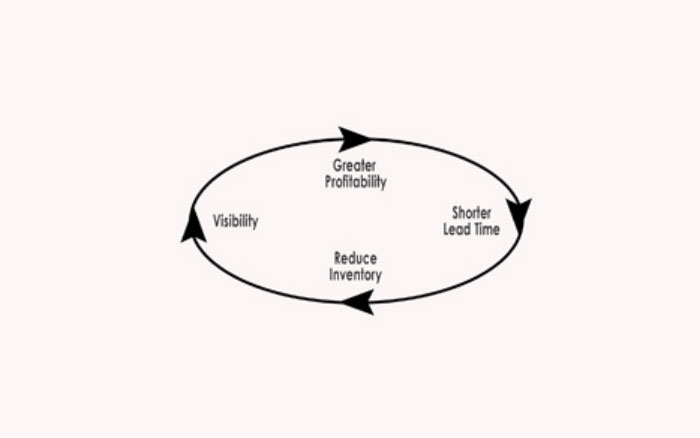

SOLUTION

We put to practice the idea that West Coast Manufacturing is an extention of your manufacturing process; we demand quality, speed, economic efficiency and innovative machining solution Our knowledge base and expertise includes the handling and machining of various types of materials ranging from plastics, aluminum and brass up to and including various aircraft super alloys, titanium, inconel and other exotic materials. Keenly aware of the convenience of value added services,

We are confident that over 20 years of machining and engineering experience are of significant value towards identifying innovative solutions to your manufacturing and/or R&D projects you may be exploring.

We are routinely provide sub assembly , assembly and kanban inventory management service. Whether you are seeking a reliable partner to research and develop a new product and/or a trustworthy supplier for a long run project, the men and women at West Coast Manufacturing are ready to fully commit to the success of your project.

KANBAN

As an integral part of your manufacturing process, we understand the importance of inventory management. As an added value service west Coast Manufacturing offers Kanban services that integrates Seamlessly to your manufacturing process.

Kanban services are evaluated and offered on a project-by-project basis. We welcome your questions and inquiry.

MACHINING

As a fully integroged high precision machine shop, West Coast Manufacturing services the needs of many industries, included among these ore, aerospace, petroleum, food, chemical, printing, warewash and many more.

With a cumulative industry experience of over 20 years, our staff includes administrative, quality control, programming and production experts.

At the forefront of technology and machinery, our stable of machines consists of the following brands; Akiro Seiki, Miyano, Hyundia-Wia, Eurotech, and Citizen.

We welcome all inquiries, production and R&D included!

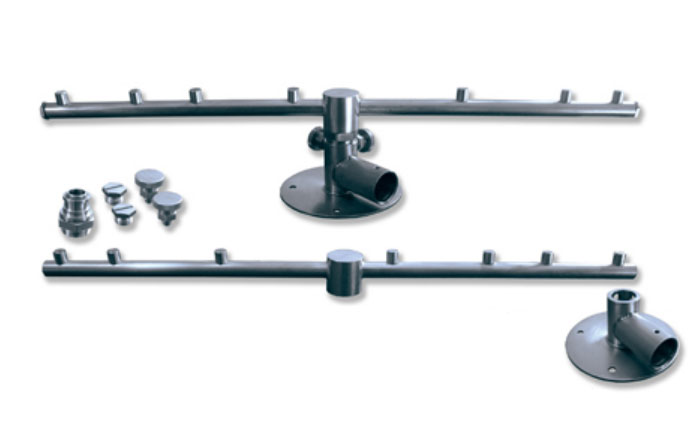

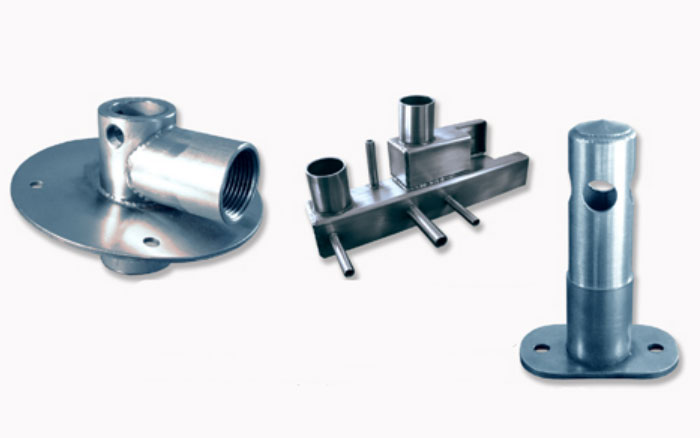

ASSEMBLY

Many precision machined parts we manufacture are assembled in the later stages of production to make a working whole.

Knowledge of each individual part allows us to efficiently assemble and deliver a working whole assembly to further streamline your production

and/or minimize downtime.

WELDING

Whereas most machine shope either outsource or do not include welding as an integral component of service offered, at West Coast Manufacturing we feel otherwise.

Welding is a natural extension to most manufacturing processes. Our in-house welding deportment consists of Lincoln and Miller Heli-Arc, both on rotary tables and fully staffed.

SAMPLE

| Description | Material | Process | Application |

|---|---|---|---|

| Spray Arm Bearing Assembly | 300 Stainless Steel | Multi Axix Miling CNC Lathe Assemble | Commercial Waterwash Industry |

| Custom Thumb Nut | 300 Stainless Steel | Multi Swiss Machining Welding In-House Polishing | Commercial Waterwash Industry |

| Printing Press Roller 6-1/2 dia. X 21” | Carbon Steel | Multi Axis Dual Spindle Lathe Assembly | Printing Industry |

| Spacer Wheel | White Delrim | Single Operation Multi Access CMC Lathe | Aerospace |

| Spanner Wrench | 6061 Aluminum Flat Bar | Vertical CNC Milling | Custom Wrench Waterwash Industry |

| Chemical Injection Body | 316 Stainless Steel Hydex 202- High Density Plastic | Single Operation Multi Axis CNC Lathe | Chemical Industry |

| Fan Nozzle | Hydex 102- High Density Plastic | Single Operation Swiss Machining Multi Axis Swiss Dial | Various Chemical Application |

| Compression Fitting Assembly | 300 Stainless Steel W/ Integrated Brass Fitting | Single Operation CNC Multi Axis Lathe Assembly | Commercial Warewash Industry |

| Spray Base Adaptor | 300 Stainless Steel W/ Integrated Brass Fitting | Single Operation CNC Multi Axis Lathe | Commercial Warewash Industry |

| Bearing Journal Housing | 300 Stainless Steel W/ Bronze Bearing Sleeve | CNC Multi Axis Milling & Turing Welding Assembly | Commercial Warewash Industry |

| Double Arm Spray Arm | 300 Stainless Steel | Multi Axis Swiss & CNC Lathe Welding Assembly | Commercial Warewash Industry |

| Manifold | 300 Stainless Steel W/ Silicon O-Ring installed to Seals | Multi Axis CNC Lathe Assembly | Commercial Warewash Industry |

| Spray Base | 300 Stainless Steel W/ Silicon O-Ring installed to Seals | Multi Swiss Machining Welding Assembly | Commercial Warewash Industry |

| Custom Thumb Nut | 300 Stainless Steel W/ Silicon O-Ring installed to Seals Stamped Sheet Metal | Multi Swiss Machining Welding In-House Polishing | Commercial Warewash Industry |

| End Cap | 300 Stainless Steel W/ Silicon O-Ring installed to Seals | Multi Axis CNC Lathe | Commercial Warewash Industry |

| V-Jet Nozzle | 300 Stainless Steel Brass | Single Operation Multi Axis Swiss & CNC Lathe | Commercial Warewash Industry Chemical Industry |

| Single Arm Spray Arm | 300 Stainless Steel | Multi Axis Machining Welding Assembly Nickle Vacuum Furnace Brazed | Commercial Warewash Industry |

| Spray Arm Post | 300 Stainless Steel | Multi Axis Lathe Sheet Metal Stamping Welding Assembly | Commercial Warewash Industry |

| Bearing Sleeve | Bronze | Multi Axis CNC Lathe Broaching Assembly | Commercial Warewash Industry |

| Spray Arm Bearing Assembly | 300 Stainless Steel | Multi Axis Swiss & CNC Lathe Assembly | Commercial Warewash Industry |

| Manifold Housing | 300 Stainless Steel | Multi Axis CNC Milling Welding Assembly | Food Industry |

| Spray Arm Bearing Assembly | 300 Stainless Steel | Multi Axis Milling CNC Lathe Assembly | Commercial Warewash Industry |

Contact us now for a free quote on your project